Bending Aluminum Tubing – Tips, Tricks and DIY Help

So you’ve decided to tackle a project that involves bending aluminum tubing, have you?

Well good for you.

Aluminum’s a strong, lightweight material that you can use in millions of different applications whether you’re bending pipe, square tube, rectangular tubing or round tubing.

But there are a few things that you need to know before you start. Some of the links on this page are affiliate links and as an Amazon Associate I might earn a tiny amount from qualifying purchases if you end up buying something through one of them.

Page Content Navigation

Bending Aluminum Tubing – What You Need to Know BEFORE You Begin

And this is important to know BEFORE you start on your project.

6061-T6 aluminum is more of a structural tubing and is often spec’d as a default when it comes to different jobs and designs that you might see. The important thing to know is that it is brittle and will most often crack if you’re trying to bend it with a tight radius.

Sure, you can get away with it sometimes as the tempering will vary slightly and you might be able to get away with it being aluminum tubing without it cracking, but I’ve found that to get consistent results you need to use a bendable grade.

And that’s what 6063-T5 is – a bendable grade of aluminum tubing. 6063-T5 is actually more readily available in pipe sizes than tubing sizes.

So if you’ve got the option, you should just order and use 6063-T5.

If you don’t have that option, there are a couple ways around it.

You can either send it to a shop that does annealing and they will essentially cook your aluminum at a certain temperature until it’s annealed to a specific grade. If you went this route, you would just tell them that you would want it annealed to a 6063-T5 state.

Then once you got your parts back, you would bend them as needed.

From there you would either leave it in it’s annealed state, or you could send it to a company that will heat treat it back to a 6061-T6 state if it’s required.

The other alternative is that you can try to anneal it by hand by heating it up with a torch and then bending it. This can take a bit of practice so be sure you are using scrap material and not your working parts if you’re just trying this out.

The Best of the Pipe Bending Machine Manufacturers

From import stuff from China, to North American or European made machines there are all sort of options out there.

But the first step on the journey is to decide on the type of pipe bending machine you’re looking for and as different manufacturers produce different types and different models when it comes to pipe bending machines.

And in the majority of cases, you will be able to bend both pipe and tube on your bending machine so long as you’re able to buy compatible dies to fit the size of material your’e trying to bend.

With that in mind, let’s look at a few of the different types of pipe bending machine manufacturers and the different machine options that are available.

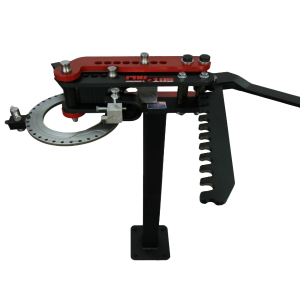

A Small Diameter Tube Bender – Floor Type Compact Metal Benders

For myself, I would always choose the floor mount style as I like to keep my workbench clear and already have vices mounted on my work bench.

So I’ve always leaned towards the pedestal floor mount style. You can move them around or you can anchor them to the floor by installing bolts in the concrete floor of your shop. If you do want to move the bender around, you can just weld some heavy plate to the base of the bender to provide a bit more stability if you don’t want to bolt it to the floor.

Now, these types of benders are most often used for bending flat stock metal, but you can also bend round stock with it as well.

The best is to have dies with a concave shape machined in them that is large enough to accept the diameter of the material you’re going to try and bend.

And then if you’re trying to bend pipe or tube, the material may want to crush around the bend if you’re trying to bend a really tight radius bend. If this is the case, you may have to fill the pipe or tube with sand and cap the ends either by welding some material on each end or threading the ends using a pipe thread and capping them with a pipe cap.

Again, these types of benders will often work fine for small diameter tube or pipe bends. You might be able to bend material up over about 1.5″ or so as your size limitation is the force you’re able to generate just by hand using the mechanical leverage of the bender and your own strength.

So the advantage of these is that they’re pretty versatile little machines as you aren’t limited to just bending pipe or tube, but you can bend flat and solid stock metal as well.

If you go this route, I would recommend the KAKA Industrial UBM-30 Floor-Type Compact Metal Bender as it comes with 14 different dies and includes a nice little scroll bending die you can use to create some ornate flat metal bends. If you’re on a strict budget, you can always get the Compact Floor Bender By Erie Tools that comes with 7 dies. But dies are expensive to either have machined up or to purchase on their own, so the Kaka bender offers a lot of value for the money if you’re going to be doing more metal fab and bending in the future.

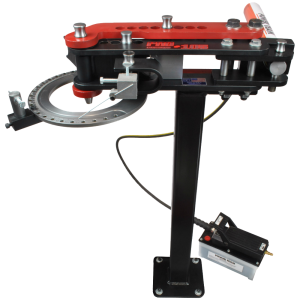

A Conduit Bending Machine – Hydraulic Tubing Benders and Pipe Benders

They are specifically designed to bend pipe or tube using a hydraulic piston were you place your material against the two upright stops, centering the material over top of the die where you want the bend and then engaging the bender.

Don’t get me wrong, they’re great machines, but making certain degree bends are difficult – these work best for bends that are fairly loose when it comes to tolerances or just standard 90 or 45 degree bends.

You can get some decent machines here.

Hydraulic Tubing Benders

And with these, you can set the degree of bend and repeat bends and you can get into bending much heavier wall material as you’re no longer relying on just mechanical advantage and your own brute strength to try and manually bend the pipe or tube.

The Cadillac of hydraulic tube benders is the Baileigh RDB-125 Hydraulic Rotary Draw bender. You can bend up to about 2.5″ OD Aluminum Tubing on it (!)

And with the degree ring guage and it’s perfect for any sort of repeat parts style bending you want to do.

The other nice thing is that you’re able to deal directly with the manufacturer and they are made in the USA – so getting dies or additional tooling generally isn’t a problem.

Typically something like this is about as big as most DIY’ers go for but for industry you can get into rotary draw NC and full CNC benders and you can get into mandrel bending as well in order to produce really tight radius dies without any wrinkling.

Unless you get a bendable grade aluminum, it is more difficult to bend without cracking. Which is why most people use aluminum in a flat form like the various ridge wallet alternatives that you may have seen floating around the interwebs.

Leave a Reply