The Best Pocket Hole Machine – What to Look for BEFORE You Buy

Choosing the best pocket hole machine to buy can be a big tricky as they are available in all shapes, sizes, weights and above all prices. Before you you get too far into the process, make sure that you take the following points into consideration.

Clamping system

- When drilling pocket holes, we want to make sure that our bearing is held securely while the drill or drill bit can penetrate without much movement. The best hand-held machines and guides should be equipped with grippers that can be adapted to the width and / or length of the board.

Locking mechanism for repeated drilling

- A locking mechanism is a simple but effective way to create repetitive pocket holes in similar size wooden panels. With the traditional pocket template, you still need to measure every board before you drill in your bearing. Pocket-hole machines have various locking mechanisms: front-to-back locking against the rear guide and even lateral locking against the stops.

Adjustable rear stop, depth gauge or depth ring

- When drilling pocket holes, we do not want the drill to drill too deep into the plate, which can create a weak band or guide hole to bolt two plates. Manufacturers can help joiners to create the perfect relationship between the pocket and the guide hole in the rear guide, the depth gauge or the depth ring. Depending on the model of the machine, you can use one or more methods to get perfect perforations every time.

High-speed drilling

- Pocket hole machines can be delivered with built-in drills. For this type of machine, it is important that the motor provide sufficient drilling speed to make careful cuts. As with drills, you will need something that is at least 1500 RPM.

Listed below are best pocket hole machine currently on the market. Some of the links on this page are affiliate links and as an Amazon Associate I might earn a tiny amount from qualifying purchases if you end up buying something through one of them.

Page Content Navigation

Fox W1833 pocket hole machine

Castle 100 Pocket Hole Jig

Castle TSM22 pocket hole machine

The Castle TSM22 is a popular pocket machine for a variety of reasons. First, the integrated drill offers up to 1780 rpm to produce clean pockets and pilot holes every time. Unlike other pocket-hole machines and the conventional pocket hole template, no additional sanding is needed to eliminate ugly splinters or uneven surfaces. The drill under the head of the unit forms a guide hole of 6 ° for a suitable resistance when two plates are connected with a screw. Additionally, to start the drilling process, the user simply starts a pedal that sends multiple exercises into the shaft, freeing your hands to avoid movement. For availability and more reviews and specs on this industrial grade machine, click here.

Quikjig 560 Porter Cable boring woodworking system

This is the only one that does not have an integrated drill for drilling holes or pilot holes. Basically, you get a pocket template with additional features, but which is characterized by its grace. You get accurate measurements for repeated drilling, well-built stops to prevent ingress and perfect pocket holes. The kit includes a necklace to measure the perfect depth for each application. The disadvantage of the QUIKJIG 560 is that it is equipped with a long drill bit for the drilling of caps and guide holes, but has no built-in storage space. If the drill falls and the pilot point fails, you will need to buy a replacement. That being said, it’s a great system for drilling holes, and you can check it out here.

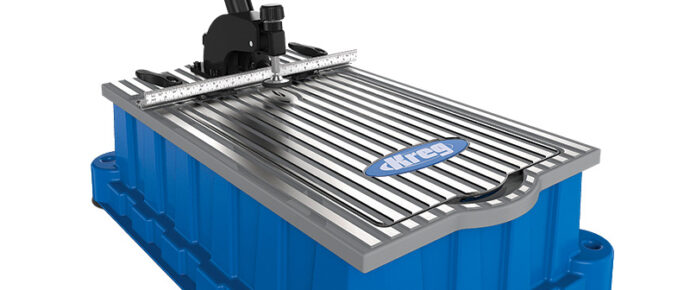

Kreg DB210 foreman pocket hole machine

DB210 from Kreg. This is another pocket-type pocket-hole machine that uses a dip grip to drill pocket holes and implantation holes. It has perfect stops to facilitate repeated drilling. The adjustable guide allows the user to control the depth of the blind hole. In addition, a dust collection port is available to remove annoying sawdust from your workplace. The 15-amp engine offers up to 2,800 rpm for specific dives for each dive. As a table machine, it is lightweight and can even be mounted on a bench for dedicated workers. It is also one of the quietest machines on the market. This machine has long been the standard among professionals and DIY’ers alike – and given the price point and performance when compared to the other machines on this list it isn’t hard to see why. A great machine. You can check it out here.

Conclusion

Pocket holes are an ingenious method of hiding unsightly screws. They ensure that two boards remain locked to prevent unwanted movement and vibration and they can also be filled with homemade or purchasable caps. They are a way that you can add a lot of strength to your project without taking a lot of time or effort in order to do so.

This method of joinery has really helped DIY’ers take their projects to the next level without requiring a lot more skill and effort. You can see how pocket holes are used in a project by reading our article DIY Storage Cabinet – A Simple Cupboard Design

Leave a Reply