[BUYER’S GUIDE] How to Choose The Best CNC Router for Small Shop

Are you in the market for a new CNC router, and are left wondering what the best cnc router for small shop is? If so, it’s not surprising, as there are a lot of things to consider when trying to choose the right model. There are many factors to consider, such as the size of your workshop, the type of materials you will be working with, and your budget. In this article, we will discuss some of the things you need to keep in mind when choosing a CNC router, we’ll give you tips on how to choose the best CNC router for your business.

First, I’ll review some of the most popular machines out there, and then I’ll get into the types of machines on the market as well as tips to consider when buying a machine.

Let’s get into this!

Page Content Navigation

Some of the Best Small CNC Routers

| Product Image | Product Name | Rating | Pricing |

|---|---|---|---|

| Genmitsu CNC 3018 PRO | ⭐⭐⭐⭐ 4/5 | 🛒 Check Price 🛒 |

| VEVOR CNC 3018 Pro | ⭐⭐⭐ 3/5 | 🛒 Check Price 🛒 |

| MYSWEETY DIY CNC Router | ⭐⭐⭐⭐ 4/5 | 🛒 Check Price 🛒 |

| BobsCNC E3 Router | ⭐⭐⭐ 3/5 | 🛒 Check Price 🛒 |

| Shark HD4 CNC | ⭐⭐⭐⭐ 4/5 | 🛒 Check Price 🛒 |

| Fox Alien CNC | ⭐⭐⭐⭐⭐ 5/5 | 🛒 Check Price 🛒 |

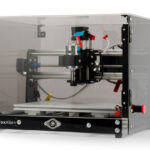

Genmitsu CNC 3018 PRO Review

The Genmitsu CNC 3018 is an all purpose cutting machine that can handle virtually any material and size you throw at it. From soft aluminum to acrylics, plastics PVC’s- even metal! It comes with a 1/2 inch kerf blade so your projects are cut cleanly without having worry about getting bogged down in one material type like many other machines on the market do today which makes this tool incredibly versatile for anyone looking into DIYing around their home or office space but also has enough power left over from its impressive capabilities if someone were actually willing use them professionally as well!

The self teaching system helps beginners get started quickly while still being able teach themselves more complex tasks through trial by error rather than the operator having to figure everything out on their own.

This machine isn’t the easiest to put together, but the manufacturer has given you an instruction book to help. But the machine is small and compact, which really helps with portability as well as being able to put it together by yourself.

If you’re looking for an accurate CNC machine that can turn your woodworking projects into masterpieces, then this is the one! The high level of accuracy and design will ensure perfect cuts every time.

The cutting area is 300 x 180 x 45mm so it’s not a huge machine, but it still let’s you cut some decent sized projects.

This machine runs using the GRBL software. And this is great as GRBL is an industry-standard and a lot of resources that can be found online for anyone who needs help with their machine.

Pros:

- This CNC router is very versatile, being able to cut many different materials.

- It’s an affordable option.

- You can upgrade it by adding a laser modules, adding even more features to your work!

- A high degree of accuracy

Cons:

- not a very big cutting area

The VEVOR CNC 3018 Pro

The VEVOR CNC 3018 Pro 500mW laser engraver is manufactured from durable aluminum and plastic and can cut through wood or metal with a high degree of precision. It also features an easy-to use design, making it perfect for your small shop projects at home!

This machine comes with 3 axes so it can cut and engrave an effective working area of 11.8″ x 7.1″ x 1.8″.

It comes with T8 screw rods to drive the machine, three stepper motors, and a 24V spindle motor to deliver a high degree of precision.

With its GRBL controlled board, the CNC machine can be connected to your computer via USB. This means that you don’t have any wiring or technical knowledge required for using this product – just plug in! The 3-in 1 design also comes equipped with PWM and TTL functionality which ensures greater practicality when working efficiently on projects both big AND small.

It also comes with a pendant control so that you can manually jog the machine into position.

This tool is great for a variety of material types and will allow you to do more than just wood. It’s also able to work on plastics, soft aluminum or acrylic paints with ease!

Pros:

- It’s extremely easy to use – making it perfect for any beginner.

- You can use it on a variety of different materials, giving you many different project options.

- It’s extremely rugged and well made.

Cons:

- There were some people who complained about it being hard to put together.

MYSWEETY DIY CNC Router Review

With the MYSWEETY, you can create a wide range of items for your home or small business. It’s easy to use and set up – making it perfect as an all-inclusive CNC router!

With its GRBL-based control system and support for Windows operating systems such as XP, 7 or 8; this tool can work with many different software packages.

Between it’s stepper motors and spindle motor, you’ll be able to get a high degree of precision on your parts.

It’s got a smaller working area than some other machines, just 160 x 100 x 45mm but it’s lower price reflects that.

This tool does a lot more than just cut wood. It can be used on plastic, acrylic and many other materials as well!

Pros:

- at just under 16 pounds, it’s lightweight.

- small machine size and footprint, so it can fit in small shops easily.

- it’s very easy to use and compatible with both windows and Linux.

Cons:

- Not suited well for large or heavy duty projects.

BobsCNC E3 Router Review

The BobsCNC E3 CNC router is a lightweight, but powerful machine. It has an easy to follow assembly process that takes less than one hour for someone with basic tool knowledge.

Even though it only weighs 32 pounds, it can handle some heavy duty projects!

The router is powered by an Arduino-based microprocessor that can be plugged into the USB port of a computer in order to control the DW660 router.

The software is written in Java, so it is compatible across most operating systems including: Windows, Linux, OSX and even Raspberry Pi!

The Dewalt router can handle router bits with either 1/8″ or 1/4″ shanks, and is moved along the X & Y axis with a belt drive. The router is moved vertically along the X axis with an acme screw.

It’s got one of the biggest working areas out there for the routers we’re reviewing here having a working area of 18″ x 16″ x 3.3″.

This is a great machine, however some users feel that the all-wood design will lead to it wearing out and decreasing its accuracy over time.

The Shark HD4 CNC Review

Thankfully, Shark hasn’t been following other manufacturers’ lead by producing cheaper machines which are not as good. In fact, the Shark HD4 is a router at a great price, with all the features you would expect from a machine costing much more.

But there are a couple of drawbacks about this machine that you should be aware of.

You can see my full review here.

The Fox Alien CNC Review

As I’ve already mentioned, there are a lot of different factors to consider when choosing a CNC router, such as the size of your project, the type of materials you’ll be working with, and your budget. That said, the Fox Alien CNC Router is a good option for hobbyists and small businesses. It has a large work area (15×15 inches), and it can handle a wide range of materials including wood, plastic, and metal. Plus, it’s priced affordably compared to other routers on the market.

You can see my full review here.

What Is A CNC Router Machine?

A typical CNC router includes a bed (where the workpiece is placed), an upright column (containing the movement system), and a horizontal arm (with the router bit at the end). The arm is able to move along two perpendicular axes, while the router bit can move up and down, and side-to-side. This allows the machine to create complex shapes by following a 3D CAD model.

High-quality, precision machine tools like this have been very expensive to buy in the past. But costs have dropped significantly, allowing hobbyists or small businesses to buy one relatively inexpensively.

What Are The Different Types of CNC Routers Available?

There are many different types of CNC machines available on the market. Some are designed for general use, while others are more specialized. If you’re looking for a new CNC machine, it’s important to know about the different types available and what each one can do. We’ll take a look at some of the most common types of CNC machines and explain what they’re best used for below.

Different Types of CNC Routers

There are many types of CNC routers. Some offer specific advantages geared towards particular industries or shops while others are all-purpose machines that can tackle a wide range of manufacturing demands.

Ranging from hobbyist kits to heavy duty, the various models on the market have a variety of features and benefits for a variety of needs. From big cutting beds to small, hobbyists and small business owners alike can find what they need at their price level without having to overspend for features they’ll never use in. Machines vary wildly by size, capabilities, costs, safety technologies used and skill levels needed to run them. And all of these things hould be considered before making your final purchase decision.

1. 3-Axis CNC Routers

A 3-axis CNC router is a computer-controlled machine that uses a rotating cutting tool to create 2D and 2.5D (not quite true 3d) dimensional objects from a variety of materials. The machine is controlled by software that tells the router where to move and how to cut.

The three axes of movement are the x, y, and z axes. The x-axis runs parallel to the length of the material being cut, the y axis runs perpendicular to the x-axis, and the z-axis moves up and down. This allows the router to move in any direction around the object being cut.

2. 5-Axis CNC Routers

A 5 axis programmable machining center or 5-axis CNC router is a machine tool that can cut on any of the five axes, allowing you to cut in almost any direction. The five axes are X, Y, Z about the XY plane, about the ZX plane, and B about the XY plane. The 5-axis router commonly would have 6 to 8 tools that can be inserted into one group of spindles to set up the high-speed/power precise tool turning. It operates quickly because it does not need to change setups often during the machining process.

5-axis CNC Routers operate by connecting together one or more work head spindles with one or more simultaneous working coordinate systems. Unlike special-purpose parts makers, these linear equipment have five axes for two-dimensional geometric shapes and four axes for three-dimensional objects, so no matter the shape you want to create it’s possible!

3. Spindle or 4 Axis Machines

The spindle is a type of CNC router that has a C-axis which rotates the workpiece in two axis and M-axis, also known as Gantry, on which the spindle head moves X and Y. 4 Axis CNC Router has XYZ axes with Z being up/down movement. The design makes more room for engravings so detail can be seen better on images or rendering on 3D models. This type of machine is typically used where there is a cylindrical design and can be an additional feature for 3 axis machines.

A 4-axis CNC router is one equipped with four motors that move along three different axes perpendicular to each other. This enables it to make very complex cuts involving 3D milling and 2D laser engraving by moving between two or more adjacent “X” areas at once.

4. Shuttle or 2 Axis Machines

A 2 axis CNC Router is a type of woodworking machine that can cut out shapes from sheets of plywood or MDF. It typically has two different, independently powered axes for controlling the router table’s movement in an X and Y-axis. In other words, it’s basically a more sophisticated table saw with specialized hardware to control intricate motions on each layer.

Answer: Essentially, a 2-axis CNC router is a machine in which a column is fixed in an up/down orientation, and the head is controlled by two axes in order to cut out parts made from wood or other materials.

A 2 axis mill is an ideal tool for making parts for cabinetry because it can do things like special edge treatments (round-over edges) quite easily. Uses for this type of machine include light fabrication, trimming, artwork reproduction, and signage material production. File size restrictions can be made with thicker than normal materials so there are no limitations on what you can make with these machines. It’s also possible to avoid over-cutting your workpiece by not flipping it 90 degrees.

5. Laser CNC Router

A Laser CNC Router is a CNC router where the workpiece is cut using a laser in a manufacturing process called laser cutting.

The technology has been used in industry for more than a decade, and many CNC routers offer a small laser cutting attachment that can be added to their existing 3 axis machine.

How Does A CNC Router Machine Work?

A CNC router is a machine that follows a design that has been programmed into its software, cuts materials with its fixed cutting wheel, and moves granular material under the fixed wheel in order to achieve the desired shapes of cuts. The limits of what can be achieved by a CNC router lie mainly in limitations on the creativity of the programmer and the cost of the tools and materials needed to make more complex designs on complex objects. In addition, there are some limitations on the complexity of design due to the feed speeds of the machine which limit how intricate some features can be made using this type of machine.

The CNC router works by using a cutting tool to produce a pattern on the surface of the material. It does this by inspecting, locating, and clamping onto workpiece blanks for machining. These functions are carried out by two main components: 1) a motion system that constrains the movement of the workpiece inside the machine and 2) it’s cutting tool assembly which coordinates the production of features on the surface of a workpiece.

How to Choose The Best CNC Router?

When it comes to choosing the best CNC router, there are a few things you need to take into account. This guide will help you figure out which CNC router is right for you.

1. What You Will Use The CNC Router For

The CNC Router can be used to create an incredible number of different products from custom designs, models, and pencil drawings. It is versatile enough to engrave wood, plastic, glass, and metals. A router is also a great tool for creating architectural design elements such as doors and window frames. There are many different types of materials that the machine can work on from plywood to aluminum sheet metal making it a valuable addition to any workshop.

You can do almost any work on a CNC router except for trying to machine hard metal types like mild steel. You can also use it to make cabinets, jigs, and fixtures, prototypes of products, as well as sculpture and part reproductions. There are dozens of other things you could do with a CNC router as well. I recommend sitting down and deciding exactly what you’ll be using the machine for as a first step to deciding which CNC router to buy, as how you use it will dictate what machine you should get.

2. Consider The Size of Your Project and How Much Space is Available

When starting a new project, it’s important to take into account the size of the project and how much shop space you have available. This ties into the point I made above, as the size of the parts you’ll be making will determine the size of machine you need to get.

3. Decide on a CNC Machine that Has All the Features You Need

As always with these things, it boils down to how much time and money you want to invest in a project. If you’ve already decided on the kind of parts you’ll be making, you’ll have an idea of what features you will need.

4. Compare Prices Between Different Brands, But Also Consider Quality When Picking Which One to Buy

Some companies offer warranties of 3 years or more whereas others offer none. Some companies might be made in the US, while others are made overseas with cheaper labor costs.

A lot of time, lower priced machines can come with lower ratings, less power, slower speeds, or shorter service life than high-priced ones.

I recommend looking at some of the different CNC router reviews that I’ve done on the site here to help.

5. Think About Whether or Not You Want An Assembled CNC Machine or If You Will Build It Yourself

There is a significant difference between an assembled CNC machine and building one yourself. An assembled machine will come with all the parts pre-assembled, saving you time and money during the build process. Additionally, many of the more complex machines can be difficult to build without prior experience or knowledge in this area.

Building a CNC machine from scratch can be a fun and rewarding project, but it requires significant time and effort. You will need to source all of the individual parts, assemble them yourself, and then configure the software and hardware to get everything working properly. This can be a daunting task for someone who is new to CNC machining, so it’s important to do your research before starting out.

6. Choose the Right Specs

Motor Type

Deciding on the motor is an important decision because it determines how fast and at what rate your cutters move.

And this, in turn, affects the torque applied to your workpiece – which ultimately impacts RPMs (or cycles per minute).

So you want to choose something that will be powerful enough to handle what you’re going to be cutting.

One thing to keep in mind is that palm routers are typically louder than water-cooled spindles and the RPM of palm routers are usually controlled manually.

But on entry level cnc units, the spindle motors they come with can often be unreliable and underpowered.

The Drive System

There are a few different ways CNC machines move along the rails.

These include an acme lead screw, a ball screw, rack and pinion and belt or linear rails.

For CNC routers, they generally use an acme screw or ball screw. Ball screws produce more precise results but are much more expensive.

Any time you use a belt drive system, they will wear out over time and this ruins the precision of your parts.

But belt-drive systems are often cheaper.

So there’s always a decision to be made when it comes to precision and cost.

What is the best CNC router for a small shop?

Ultimately, the best CNC router for a small shop is one that meets the specific needs of that particular shop owner while also staying within budget.

Concluding Thoughts on Finding The Best CNC Router for Small Shop

When deciding on the best CNC router for your needs, you should consider how often it will be used, what type of parts you will make, and what type of material is being cut. If you are cutting light materials like foam or paper then a small tabletop machine might do just fine. On the other hand, if you need to mill aluminum or steel then that would require a much more powerful tool with different capabilities.

When people were looking for the best cnc router for small shop they also wondered about:

What is the best cnc router for small sign shop?

It will largely depend on the size of the signs that you will be making. That said, I think the the Fox Alien CNC router is a fairly inexpensive way to get started with a great CNC router.

Is the raptor CNC router good?

The raptor CNC router is a high-quality machine, as it has been engineered with a number of thoughtful features.

The raptor CNC router does not have an AC motor due to the complexity and potential for servo failure. Instead, this particular model is driven by a TTL compatible stepper motor that moves from 0° to 180° in 1.8° increments. This means that there are no backlash gears or timing belts, which helps eliminate longitudinal vibrations and disturbances during operation. The other thing about this device that’s worth mentioning is that there’s no audible sound made when working with this tool thanks to its integrated vibration isolation system.

Is the vendo cnc router a good option?

In general, vendo CNC routers are a good option for those who want quality machines at an affordable price. They are also beginner-friendly, meaning they are relatively easy to operate and don’t require a lot of experience or expertise to get started. So if you’re just starting out.

What is the best small cnc machine?

I’ve been pleasantly surprised by Nexwave CNC machines and some of their smaller competitors like the Fox Alien CNC.